Configure your product

Description

Due to supply chain cost increases, a surcharge may be added at checkout.

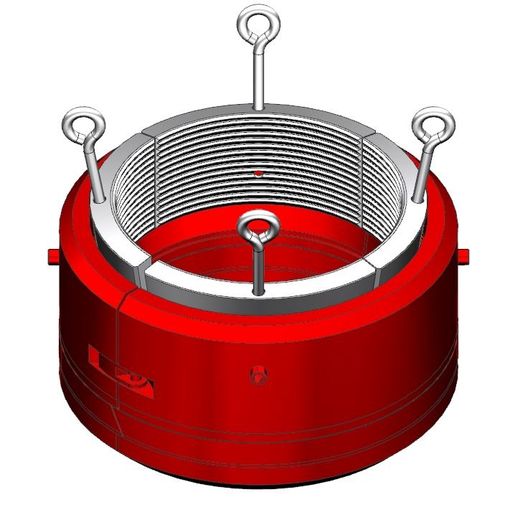

TechnipFMC offers dependable slip-type casing hangers that are available in automatic and non-automatic varieties.

Casing hangers have three main functions:

- Suspend the casing load from a casing head or spool.

- Centralize the casing string in the head or spool.

- Provide a method to allow sealing against the inside of the wellhead to contain pressure in the annulus between its casing string and the previous string. In some cases, a separate seal ring or packoff bushing is necessary to provide the seal.

TechnipFMC’s C-22 and C-29 automatic slip hangers have an integral, compression-type seal mechanism that automatically actuates with the weight of the casing string. In some situations, Lockdown Screws (LDS) may be used to provide additional setting load. The C-22 and C-29 style hangers use a split packing manufactured from nitrile or HNBR material. These materials cover both sweet and sour service applications (AA through HH). Our casing hangers meet API 6A’s PR1 or PR2 requirements.

C-22 and C-29 Features:

- Fits all Surface Wellhead C-22/C-29 casing heads and spools.

- Designed to suspend typically encountered casing loads.

- Provides automatic packoff sealing.

- Only 50,000 to 60,000 pounds of casing load is normally needed to energize the annulus seal.

- Hangers can be lowered through blowout preventers and landed before or after cement has set.

- Incorporates spring-loaded latch and heavy-duty hinge.

- Provides interlocking slip segments.

TechnipFMC’s C-21 and C-24 non-automatic slip hangers do not have an integral or self-actuating seal mechanism, but instead have a separate seal ring, which must be mechanically locked in place. Non-automatic hangers are typically used when insufficient casing load is available or when cementing back to the surface.

C-21 Features:

- Fits all Surface Wellhead C-22/C-29 casing heads and spools.

- Designed to suspend typically encountered casing loads.

- Independently installed, interference-energized packoff sealing ring.

- Slip and bowl assembly can be lowered through blowout preventers and landed before or after cement has set.

- Incorporates split design with easily engaged latching cap screws.

- Provides interlocking slip segments.

*The product images shown are for illustration purposes only and may not be an exact representation of the product.